Looking for specific data about plastic waste in Copenhagen?

Plastic waste in numbers

Waste generation:

In 2020, approx. 11.700 tonnes of plastic waste ended up in the residual waste stream in Copenhagen according to data from a recent residual waste composition analysis.

The same year, approx. 4.100 tonnes of household plastic waste was collected in the city, which means that the total household plastic waste generation in 2020 was approx. 15.800 tonnes (the number does not include plastic packaging waste from the industry and service sector).

Collection rates:

When the FORCE project was initially launched in 2016, the City of Copenhagen only collected an annual amount of 1.733 tonnes of post-consumer plastics. In 2020, the collection rate had increased to 4.100 tonnes corresponding to 6,42 kg per capita. One way to significantly increase collection is to allow citizens to sort all types of plastic waste (incl. flexibles) in the same container.

Waste composition:

The data, which is based on an automatic batch sorting test of approx. three tonnes of plastic waste followed by a manual sorting of approximately 700 kilos of sorted waste carried out in 2020 shows that PP, PE, and PET take up 83 % of the total plastic waste, while carbon black plastics take up 10 % of the total weight. The rest is other plastics, e.g. PS, ABS, PLA). Furthermore, PE-films and foils take up approx. 41 % of the weight of the collected waste.

Automatic sorting:

It is possible to sort a 96 % ”clean” post-consumer PE-foil fraction from mixed, household collected plastic waste using one run past a windshifter and one run for the windshifter material under a NIR scanner.

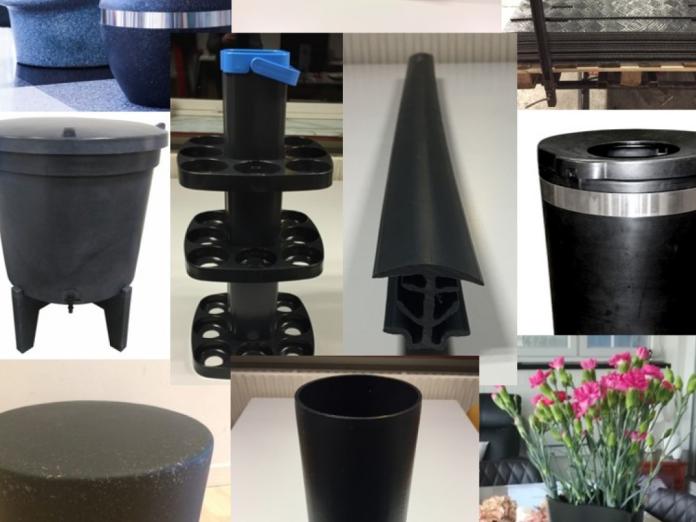

Recycling of post-consumer flexible PE: mixed post-consumer flexible PE can be recycled into a raw material suitable for production of a variety of products either as a 100 % substitute or as a blend with post-industrial PE. Examples of products that can be made with this material include: ground mats (sheet extrusion), furniture (rotational moulding), profiles (extrusion), waste bins (rotational moulding).

Design-for-Recycling:

New packaging must be designed in ways to enable high-quality recycling when the products become waste. A design-for-recycling manual has been developed, which provides guidelines to product manufacturers and purchaser.

As an example, the FORCE project has found that printing inks on foils and packaging has a detrimental effect on recycling, because the colours are turned into gas during the extrusion process of the secondary raw material. This results either in

- a more expensive raw material (because of longer processing time at the recycler) or

- a raw material of worse quality (because the gas gets trapped in ”gas pockets” inside the pellets).

Actual recycling rates:

There is a loss of approx. 40 % of the weight of the films following the recycling process. The far greatest part of the loss is due to moisture content, while the rest of the loss consists of washed dirt and sand, heavy plastics which are separated during the float-sink separation step or loss of foil in the recycling process. This means that the actual recycling rate for household collected films following the used method is approx. 80-90 % of the added dry matter.