Results from automatic sorting of recyclable textiles

Image

Post-consumer recyclable textiles (non-wearables)

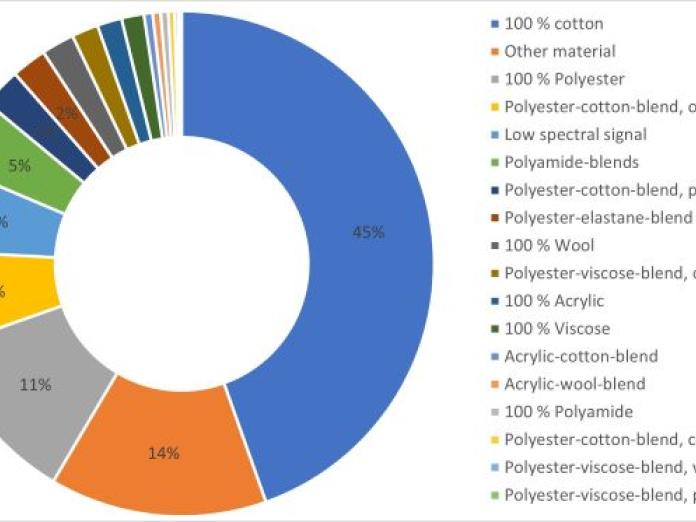

The sorting took place at SOEX Recycling pilot automatic sorting plant in Wolfen, Germany. SOEX Recycling used NIR-detection to separate the textile waste into 17 different material streams.

Key learnings from the sorting tests:

- Although a collection scheme is targeted only for recyclable textiles (non-wearables), it would most likely include a reusable fraction of wearable textiles.

- The market for sorting and recycling of non-wearables is currently not self-sustaining. Existing treatment solutions rely on revenues from wearable textiles for reuse. As collection schemes targeting recyclable textiles (e.g., in Denmark) become more and more widespread, the reuse & recycling industry must adapt to the new political requirements for recycling. The cost of recycling has to be compensated by a third party, e.g., producer responsibility scheme or increased demand for circular solutions.

- Non-wearable textiles (textiles suitable for recycling) must be sorted e.g., in different material compositions before they can be recycled. In the sorting tests, the recyclable fraction was sorted into 17 different material categories that can be used to produce secondary raw materials (figure)! This demonstrates the complexity of the textile qualities.

- The near infrared (NIR) scanners used for automatic sorting have a hard time detecting and sorting dark & black textiles. This challenge is well-known by sorting plant operators treating plastic packaging waste.

- The first batch consisted of 4.9 tonnes of recyclable textile waste collected from the municipality of Rødovre. The collected textiles were pre-sorted by the company Trasborg Denmark who took out the reusable and salable qualities leaving only the recyclable textile waste.

- The second batch consisted of 6.8 tonnes of recyclable textile waste, which was the leftovers from presorting at AffaldPlus’ sorting plant in the city of Næstved.

- Both batches represent an approximate version of the new waste fraction “recyclable textile waste” for which all municipalities in Denmark are required to set up a separate collection scheme by the 1. of July 2023 at the latest.

- SOEX estimate is that the non-wearable fraction from the tests is comparable to non-wearable fractions of textile waste from other European countries, e.g., France.

Key reflections:

- Most non-wearable textiles today are mechanically recycled and used as secondary raw materials for different industries, e.g., automotive industry, construction industry and the textile industry . Mechanical recycling is only used to a smaller extend to produce new textiles. Some mechanical recyclers are able to achieve a textiles-to-textiles approach.

- Chemical recycling currently takes place to a limited extent as the processes are under development. Only specific fractions of the non-wearable textiles, cotton and polyester, can today be recycled chemically at a commercial level.

- The lack of standards for the products coming out of sorting operations for non-wearables, hampers the establishment of a well-functioning market. There is a need to develop industry standards for sorted and baled recyclable textile qualities.

Get a copy of the reports

If you wish a copy of the full reports from the sorting tests at SOEX Recycling, please contact us.

- Batch 1 sorting results

- Batch 2 sorting results